Backfire Boomerangs

They just keep coming back.

Process

Backfire Boomerangs is nearly a completely green operation. All processes are highly efficient and create no waste. The raw materials are also completely natural and no synthetic products are added. It is our desire to do no harm to the environment, while still creating the perfect boomerang.

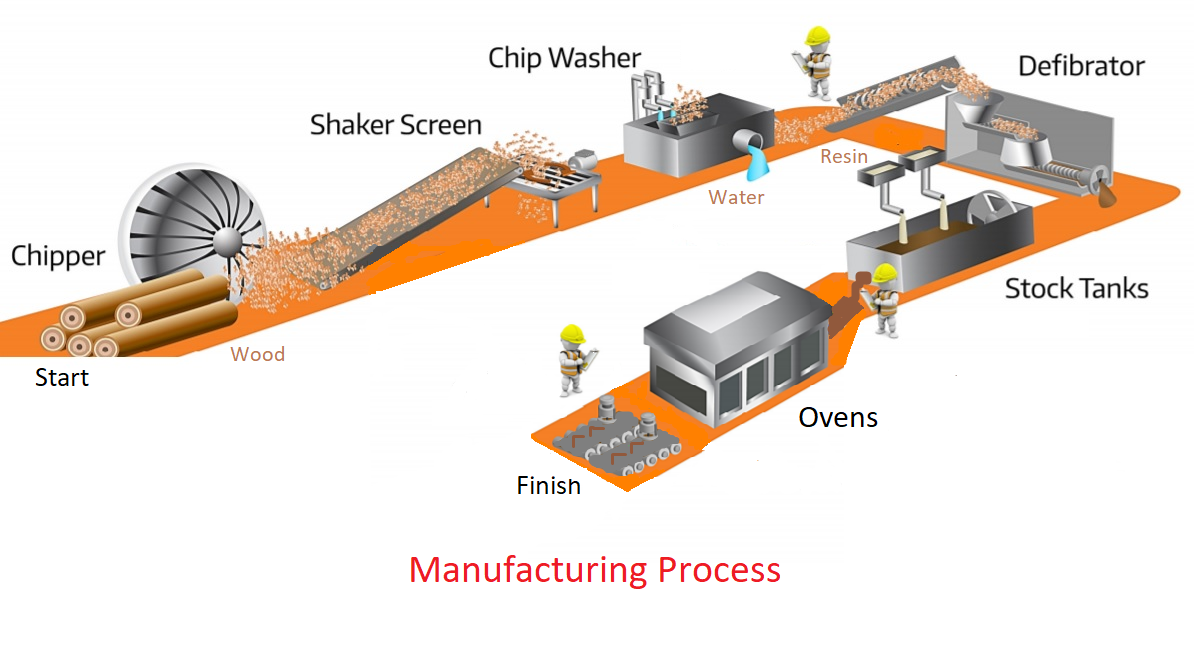

The complete process used to manufacture all of our boomerangs is a trade secret, but it can be simplified into 6 steps. Here are the steps we use to create the best boomerang product on the market today:

- Grind the wood into chips – Wood from trees has many imperfections and it is our desire that our products are perfect. Therefore, we take logs and send them through the chipper to create wood chips.

- Wash the wood chips – It is important to remove any substances off of the wood, including the resin which we collect in this process, and dampen the chips to make them more malleable.

- Put wood chips in our state of the art defibrator – Then we want to grind the wood down into a grain to be molded into any shape.

- Add resin – We will use natural resin collected in step 2 and add more if needed. This will serve as an adhesive and hold our wood fiber together while also serving as a nice glaze to keep the product smooth. We will want to keep the mixture moist, so the adhesive doesn’t harden.

- Mold the mixture – Put the mixture into engineered molds and add heat to harden into a perfectly shaped boomerang.

- Add stain – Finally, we apply a natural coat of stain in any of the three colors offered to keep the boomerang smooth and aerodynamic.